Warehouse Locations

It is helpful to structure your warehouse in at least 3 locations – Goods In, Goods Out and the actual Storage area.

In addition, you may also wish to maintain a Scarp area, and one for Returned goods.

Goods In

Inventory that have been freshly been purchased or otherwise entering the inventory from a different source, is stored in either the

- Partner Locations / Vendor, if stock is being expected, or

- In a specific physical warehouse where it is being stored.

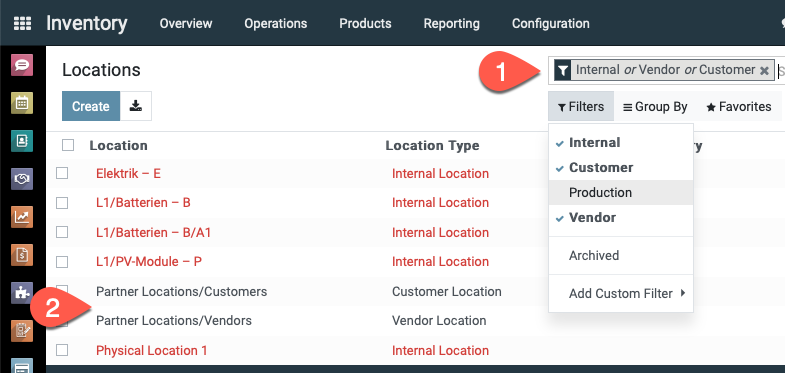

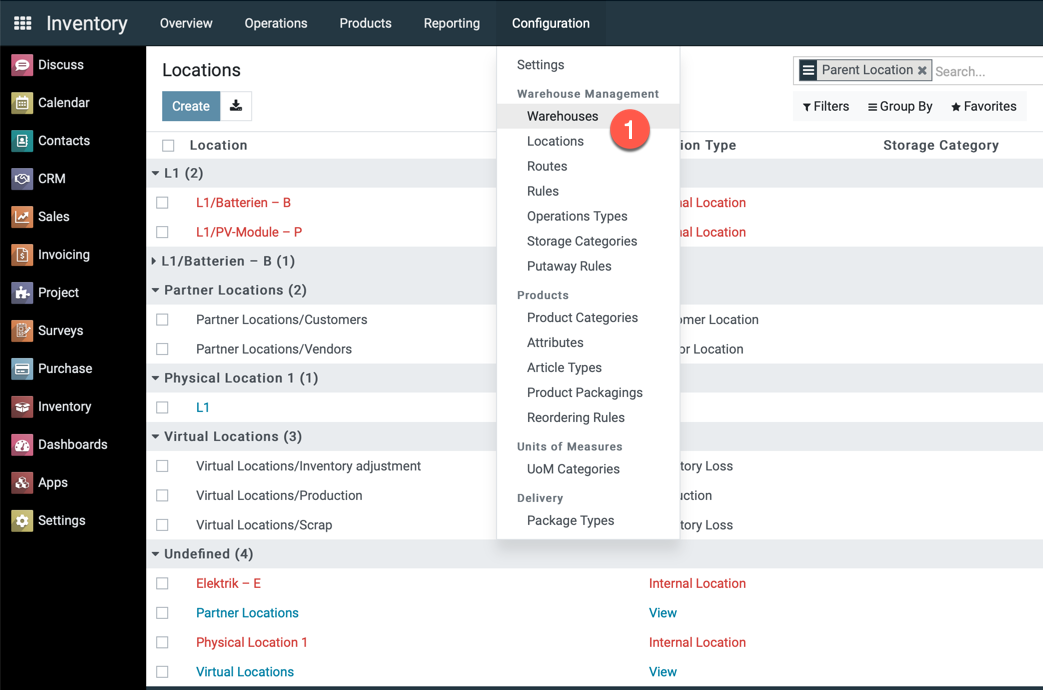

In this view, the Storage (Internal, Physical) and Customer and Vendor Partner locations are shown under Configuration → Locations.

Planning Issues

By default, the Receipts operation on the CommerceCore™ Inventory dashboard shows an overview of all Planning Issues – the shipments that are either pending delivery from Vendors to your warehouse, or delivery pending from your warehouse to Customers.

Goods Out

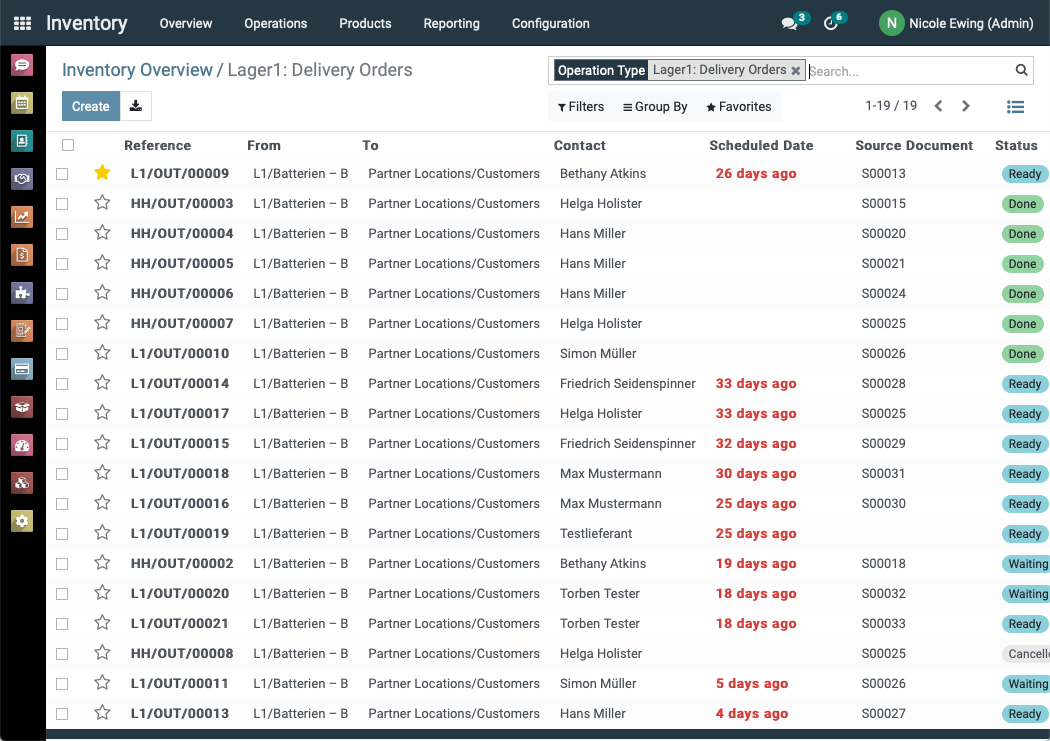

Outbound Orders pertaining to transfer of goods from a Storage location to a Customer location are listed unter Inventory Overview → Delivery Orders.

The status Done pertains to orders that have been shipped out to customers, an the status Ready pertains to orders that have been released for shipment by the Sales processes/organisation, but awaiting receipt of some missing line items.

Further filters can be applied incase you are dealing with a large order throughput. Test it out in a free-trial.

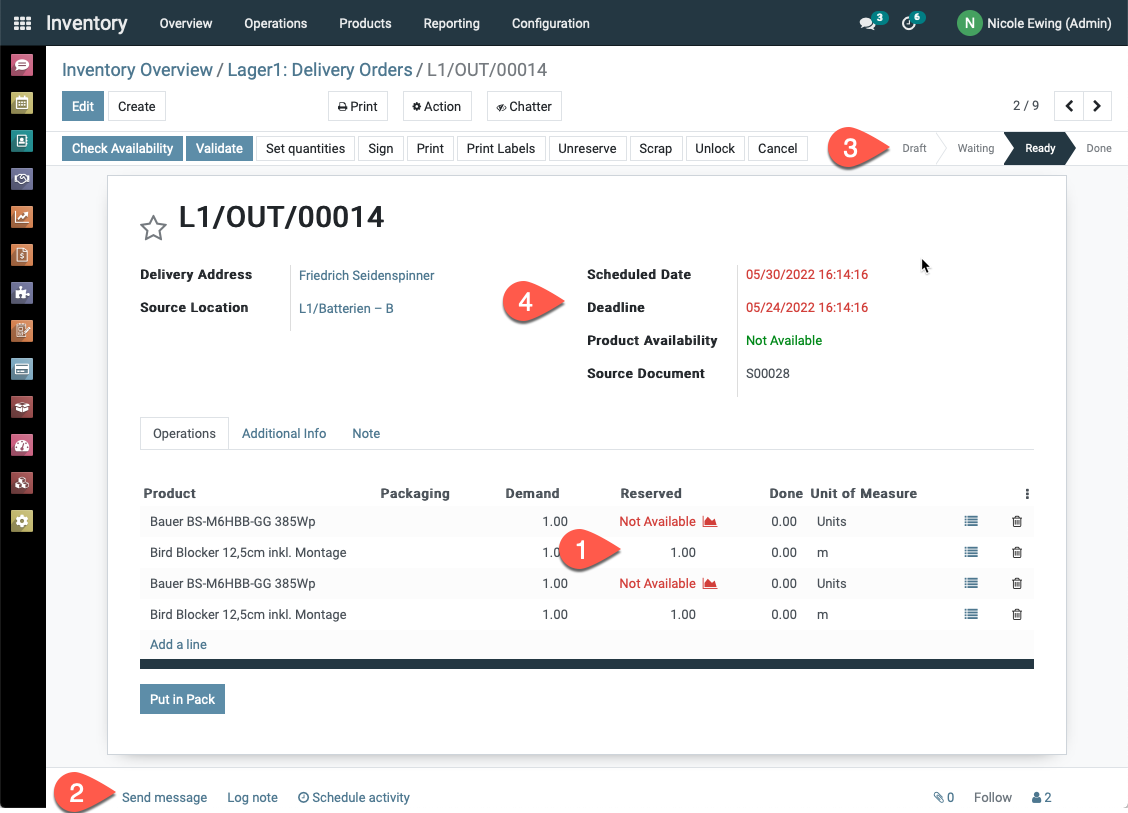

Digging deeper into each of the Delivery Orders provides further details of the specific components being shipped, as also other order-related dates. As always, CommerceCore™ it is possible to communicate with your business partners using the Chatter.

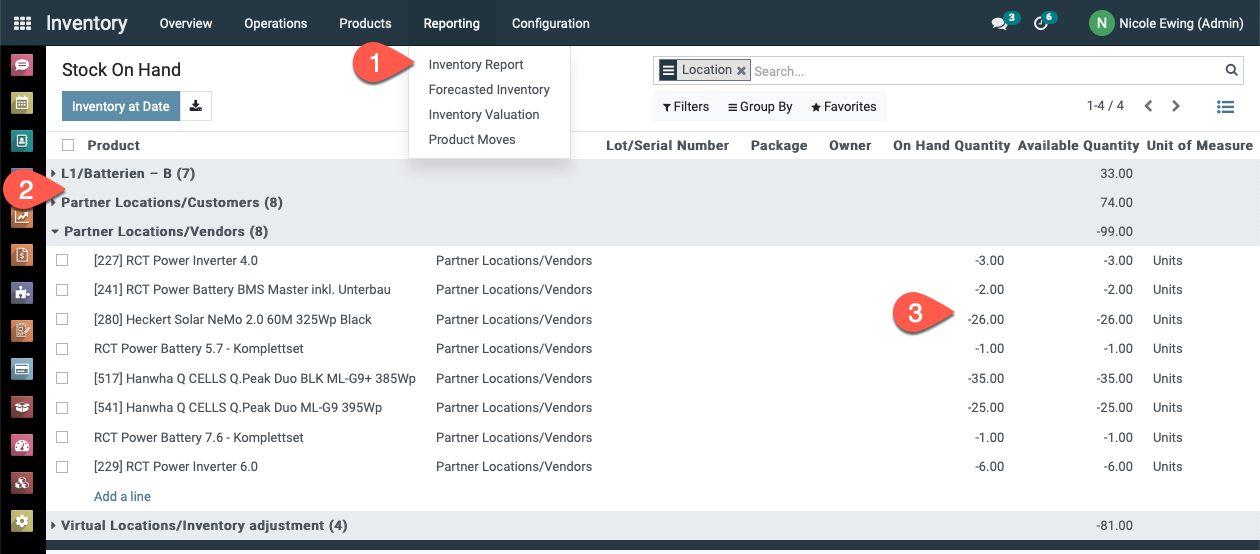

Storage

The stock held in all warehouse locations can be overviewed under Reporting → Inventory Report. Available quantities, even if in deficit can be viewed for every product being stored.

See Inventory Reports below.

Inventory Reports

Stock on Hand

In case a single product is being stored in multiple locations, it is possible to group by Product, to find out how much stock is available spread across all of them.

Alternatively, it is possible to group by Warehouse Locations.

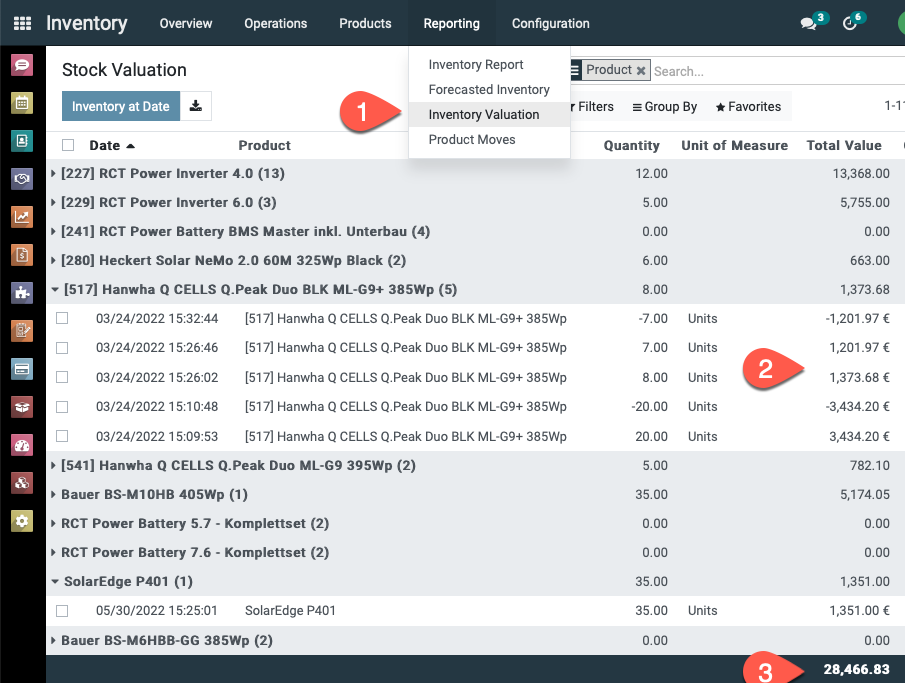

Inventory Valuation

Stock Valuation

How much purchase value is being stored in your warehouses is certainly a data-point that you'd like to know as accurately as possible at any given time. This is shown under the Reporting → Inventory Valuation.

Valuation of specific products is shown accurately in a double-entry method.

The Stock Valuation report also summarises the currently available quantities on hand.

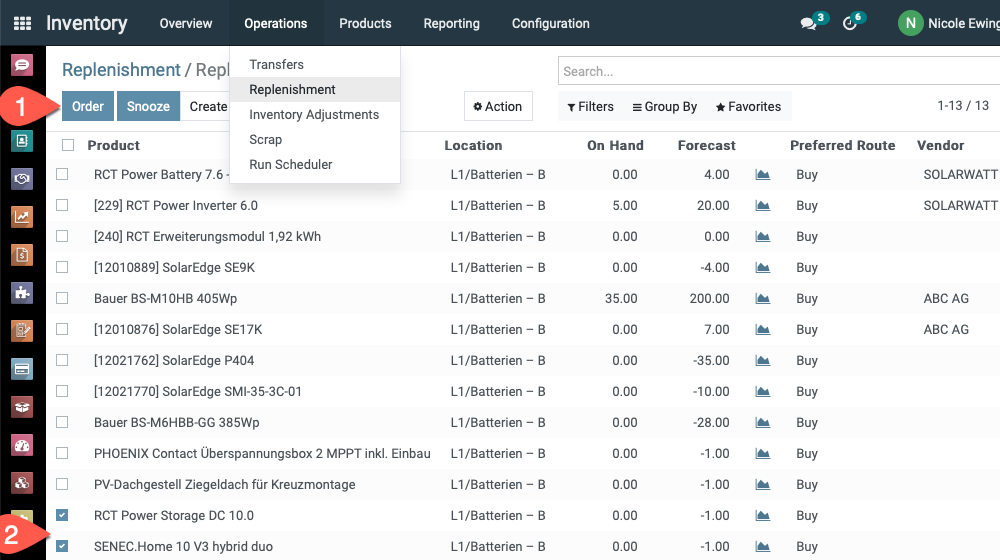

Stock Replenishment

Replenishments

Replenishment is a powerful feature of CommerceCore™ to automatically list out the individual components/products that are needed for various delivery commitments and channel them into the Purchase process.

An overview of various pending procurement demands in the company are listed under Operations → Replenishment.

Purchase Orders

On the Replenishment overview, it is possible to select specific products, note the number of units that are in demand and generate a Purchase Order (PO) automatically. Don't worry, the PO is not sent to the Vendor, rather it awaits in a Draft status for your approval.

This makes it extremely convenient for purchase departments using CommerceCore™ to stay on top of their procurement requirements.

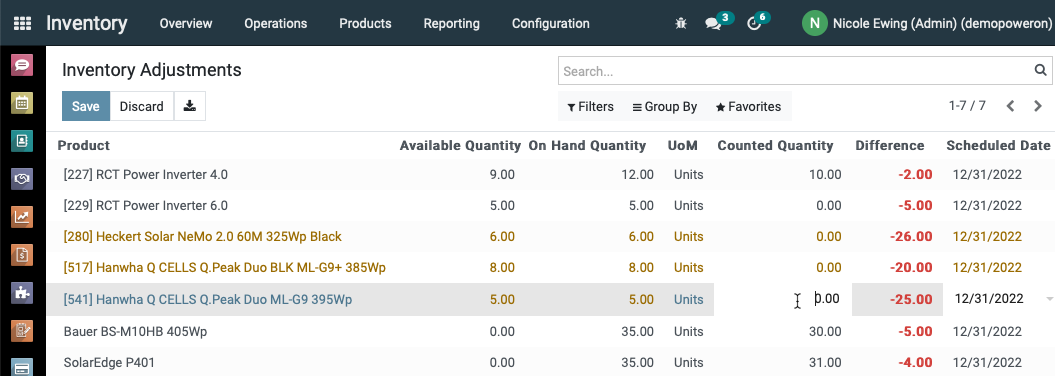

Manual Inventory Adjustments

Counted Quantity

Often it is helpful to count physical stock in the warehouse and update the same in the system. To facilitate this CommerceCore™ provides an Inventory Adjustment table under Operations → Inventory Adjustments to manually update actually counted stock.

Difference

Minus any stock that is pending arrival from a Vendor, the Difference column shows the discrepancy between the physical stock and system stock values.

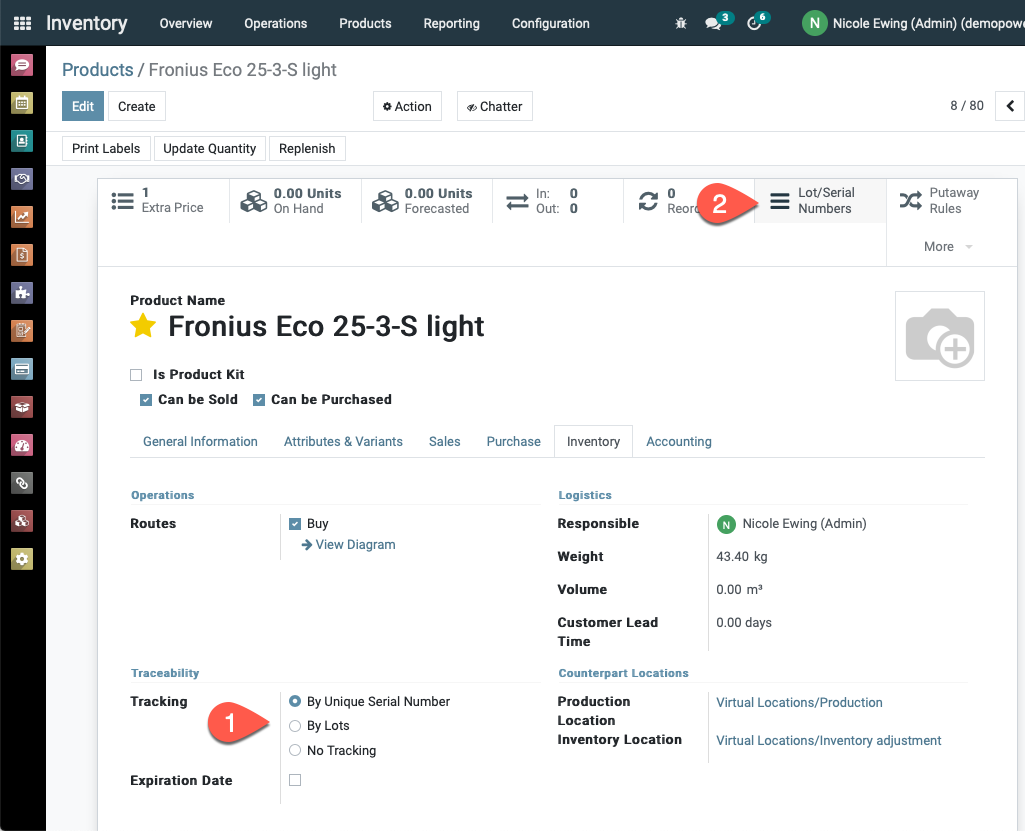

Lots & Serial Numbers

For certain products, such as food and beverage, or even those where manufacturer serial numbers have to be tracked, CommerceCore™ provides Traceability.

Products can be tracked by

- Unique Serial Number, or

- Lot number

Lots and Serial numbers can then be maintained in a special view.

Test it out on a free trial!

Multiple Warehouses and Locations

CommerceCore™ allows the storage and transfer of your physical inventory in an extremely flexible fashion.

You can structure your storage space into multiple locations, either owned by you, or rented space at fulfilment service providers, or even dropshipping vendors who are shipping on your behalf.

Integration with Sales

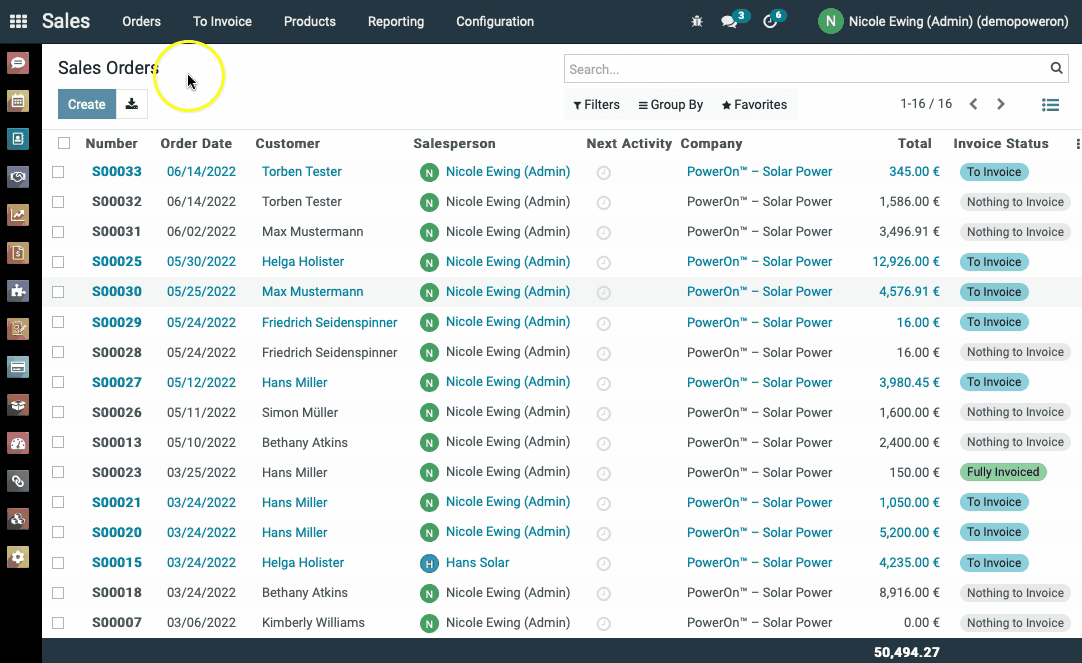

Confirming Sales Orders

Confirming Sales Orders automatically creates Delivery Orders as preparation for shipping the goods out to the customer. The location from which the shipments will be made are preselected based on the storage location of the products.

Warehouse staff have a clear handover from the sales organisation. Picking lists, barcode processes and routing of stock are thereafter managed by the warehouse organisation.

Integration with Purchase

While working in the Inventory module, it is possible to perform a variety of replenishment operations to create procurement orders (or PurchaseOrders, PO) for the purchasing department.

Please see Stock Replenishment above, and test out the software yourselves.

Stock Replenishments can also be automated.

Powerful Routing Mechanisms

CommerceCore™ Inventory is based on a powerful stock-routing engine, which allows for flexible rules to be set up for moving stock around owned warehouses as well as Vendors and other partners such as fulfilment agencies and dropshipping vendors.

In addition routing rules can also be written for triggering purchase operations, or performing certain services (in those cases where the Sale involves the delivery of a service in addition to physical products).

Discuss your routing situation with our Business Analysts by obtaining a free demo of how your stock management situation can be set up in CommerceCore™.